Chemical And Pharmaceutical Equipment Suppliers

Changshu Longyu Chemical Equipment Co., Ltd. was founded in 1997 and registered as its current name in 2009. The company is located at the west foot of Yushan Mountain in Changshu with beautiful scenery, on the west bank of Shanghu Lake with rippling blue waves, with Shanghai in the east, Wuxi in the west, Zhangjiagang in the north, and Suzhou in the south. The traffic is very convenient. The total area is 14,000 square meters, with more than 50 employees, including technical and management personnel, engineers, etc., with 3 invention patents and 19 utility model patents.

The company has passed the ISO9001 international quality system certification and has a D1.D2 level pressure vessel manufacturing license.

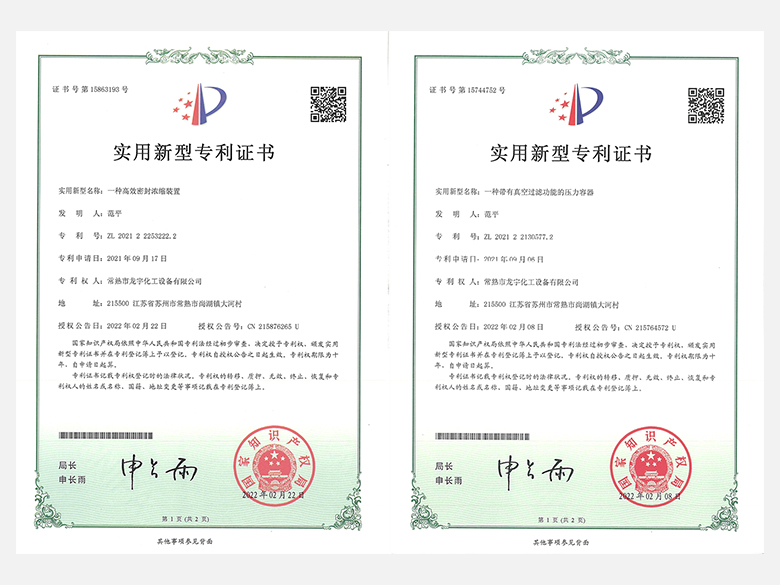

Patents View More

More than 20 years of technical experience

Have Managers and Engineers

Product independent research

3 invention patents, 19 utility model patents

Through quality certification and manufacturing license

Create reliable products for customers

Perfect after sale service

Continuously improve service quality as the pursuit

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn moreR&D and Production of Chemical Equipment

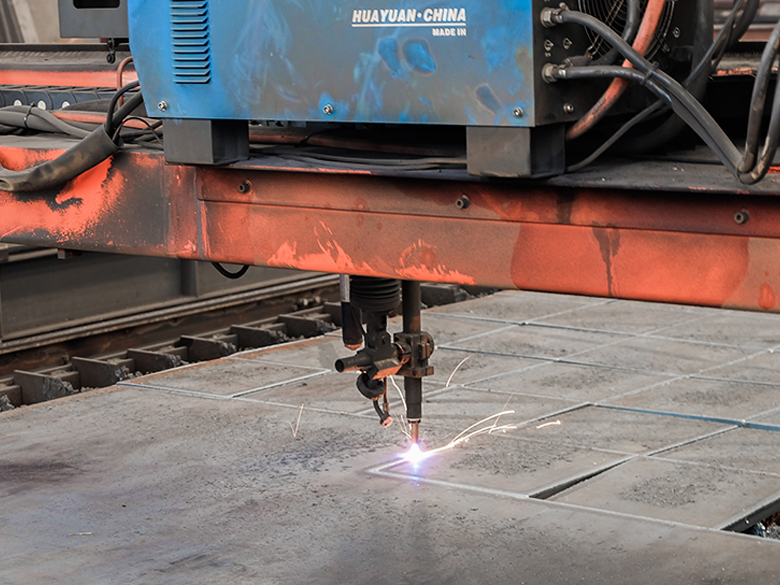

Covering an area of 14,000 square meters, the factory scale integrates from product research and development to finished product sales to ensure product quality.

With technical and management personnel, engineers 50 people.

With different mechanical processing equipment and testing equipment.

Invention Patent

Utility Model Patents

The company has passed the ISO9001 international quality system certification and has a D1.D2 level pressure vessel manufacturing license.

Products include reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produce civilian glycerin equipment and glass-lined equipment products.

Adhere to technological innovation and promote the sustainable development of the company as the goal.

Products are widely used in petrochemical, pharmaceutical, food and power industries.

Has been sold to Guangdong, Inner Mongolia, Shandong, Hebei, Anhui, Zhejiang, Tianjin, Shanghai and other parts of the province, and has been exported to Thailand and other Southeast Asian countries.

The quality policy is "strengthen process control, produce high-quality products, manage continuous improvement, and ensure customer satisfaction".

Create reliable products for customers and improve service quality as the pursuit.

Strive to become a high-quality supplier of chemical and pharmaceutical equipment.

Be sincere and do things with heart

The core of the hydrogen peroxide coalescer is liquid-liquid coalescence separation, which achieves efficient removal of trace water or organic phases in the hydrogen peroxide system through three steps of "coalescence filter capture small droplet coalescence gravity/interception separation". It is commonly used in production scenarios such as oil-water separation of residual liquids and purificat

Chemical Equipment is a general term for machines and equipment used in chemical industry production. In chemical production, in order to process raw materials into finished products of a certain specification, a series of chemical processes such as raw material pretreatment, chemical reaction, and separation and purification of reaction products are often required.

The falling film evaporator is a liquid film, low-temperature, short-term, and efficient evaporation and concentration equipment. With its high heat transfer efficiency, short material heating time, low operating temperature, less coking, less foaming, continuous stability and other technical advantages, it is widely used in heat sensitive, medium low viscosity, low scaling tendency, and easy foam

The outer coil stainless steel tower, with its advantages of corrosion resistance, high heat transfer efficiency, and compact structure, is widely used in the environmental protection industry, mainly concentrated in four major fields: waste gas treatment, wastewater treatment, solid waste/hazardous waste disposal, and resource recovery. The following are specific application scenarios and core ro

The heat transfer efficiency of the outer coil stainless steel tower is high, and the core is the structural design of the outer coil, which optimizes the core elements of inter wall heat transfer from four dimensions: heat transfer area, heat transfer medium contact mode, heat transfer path, and fluid flow state. Combined with the material characteristics of stainless steel, the overall heat tran

Tube and tube heat exchangers, with their sturdy structure, high heat transfer efficiency, high temperature and pressure resistance, and wide applicability to various media, are the core heat exchange equipment in the energy industry. They are widely used in multiple sub sectors such as thermal power, nuclear power, new energy, and oil and gas extraction and processing. The specific application sc

The reboiler at the bottom of the tower is a crucial supporting device for chemical separation equipment such as distillation towers and absorption towers. Essentially, it is a high-efficiency heat exchanger installed at the bottom of the tower (the reboiler at the bottom of the tower), whose core function is to provide continuous heat and gas phase reflux for material separation within the tower,

The outer coil stainless steel tower is a core non-standard pressure vessel equipment in the petroleum refining industry. It uses stainless steel as the main material of the tower body, and the outer wall of the tower is surrounded by a coil structure. It has the characteristics of corrosion resistance, high temperature and high pressure resistance, high heat transfer efficiency, and flexible oper